In automotive LED lighting, long-term reliability is not only about brightness. Many failures and complaints come from structural wear, corrosion, and finish instability after months of heat, vibration, moisture, road salt, detergents, and repeated thermal cycling. That is why the surface treatment of metal parts—such as housings, bezels, retaining rings, heat-dissipation structures, and other aluminum components—matters. In this article, we explain what anodizing is, how it works, the main anodizing types, and why anodizing is widely used for LED headlight bulbs and small automotive bulbs components in real-world environments.

1. Why Automotive Lighting Components Need Strong Surface Protection

LED headlight bulbs and small automotive bulbs operate in places where surfaces are constantly challenged. Vibration can loosen interfaces and create micro-abrasion. Moisture and road salt can trigger corrosion at edges and fasteners. Thermal cycling can expand and contract metal parts, stressing finishes and seals. In this environment, a stable surface finish helps parts stay cleaner, tighter, and more consistent over time—reducing avoidable after-sales issues.

2. What Is Anodizing

Anodizing is an electrochemical surface treatment that converts the surface of a metal—most commonly aluminum—into a thicker, tougher oxide layer. Instead of adding an external coating like paint, anodizing grows a protective layer from the metal itself. The result is a surface that is typically:

- More corrosion-resistant

- More wear-resistant

- More stable in appearance

- Better suited to harsh automotive environments

3. How Anodizing Works (and Why It Doesn’t Peel Like Paint)

Aluminum naturally forms a thin oxide layer in air, but that natural layer offers limited protection. Anodizing strengthens the same concept in a controlled way by building a thicker oxide layer that becomes part of the metal surface.

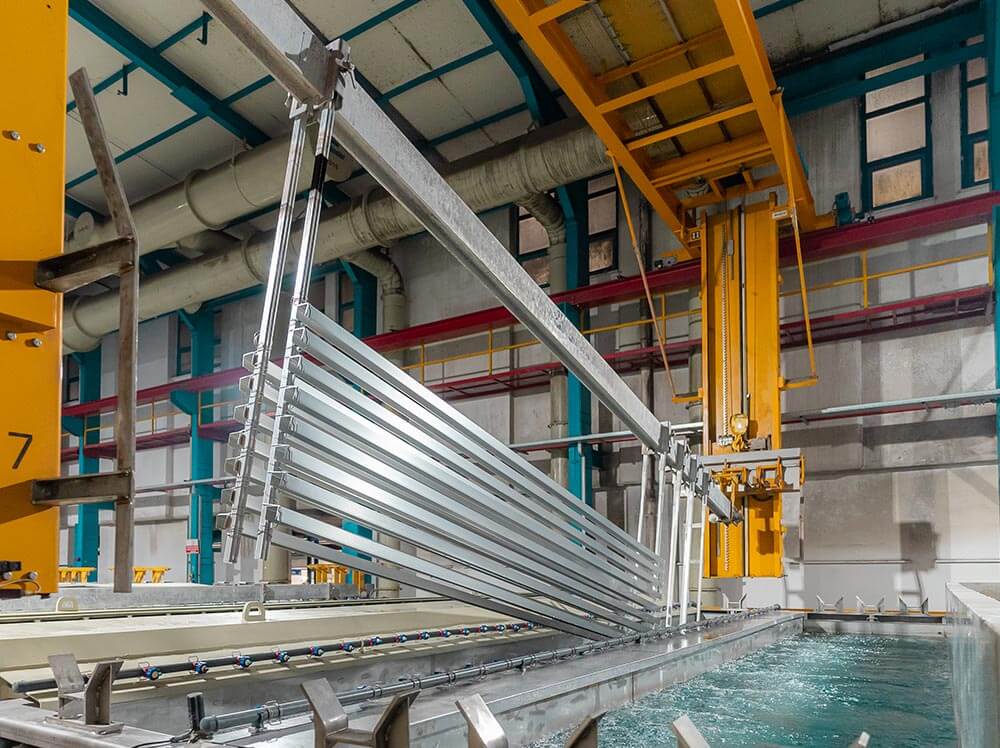

3.1 Typical anodizing steps

- The part is cleaned and prepared to remove oil, dust, and oxidation

- The part is immersed in an electrolyte bath (commonly sulfuric acid)

- The part acts as the anode (positive electrode), with a cathode in the bath

- Electrical current drives oxygen-related reactions at the surface, forming a thicker oxide layer

- The porous oxide layer is sealed to improve corrosion resistance and stability

3.2 Why it resists peeling

A key advantage is that the anodic oxide layer is integrated into the aluminum surface rather than sitting on top like a film. Under vibration, handling, and long-term use, this reduces the risk of peeling, chipping, or flaking that can happen with surface-applied coatings.

4. A Brief Industry Background

Anodizing became industrially important in the early 20th century and expanded during World War II because it helped protect lightweight aluminum parts from corrosion in harsh service environments. After that, it moved into broader commercial use across automotive components, architecture, and consumer electronics.

Later process improvements enabled colored anodizing. Dyes can be introduced into the porous oxide layer before sealing, producing stable color and a refined metallic appearance that generally holds up better than untreated aluminum in long-term use.

5. Main Types of Anodizing

Different anodizing methods exist because applications require different balances of cost, thickness, corrosion resistance, wear resistance, and downstream bonding performance.

5.1 Sulfuric acid anodizing (most common)

A versatile and cost-effective option used for both protective and decorative needs. It supports stable surface protection and can also support dyed finishes when appearance is important.

5.2 Chromic acid anodizing

Typically produces a thinner coating with strong corrosion resistance. It is more specialized and is less common in many markets today due to tighter environmental requirements.

5.3 Hard anodizing / hardcoat anodizing

Uses lower temperatures and higher current density to create a thicker, harder layer for maximum wear resistance. It is often selected when parts face frequent friction, handling, or abrasion.

5.4 Phosphoric acid anodizing

Often used as a pre-treatment for adhesive bonding, where the surface structure can improve adhesion performance in specific assembly designs.

6. Why Anodizing Fits LED Headlight Bulbs & Small Automotive Bulbs Components

In automotive lighting, the real question is not whether a bulb works on day one—it is whether the system stays stable after months and years of real use. When aluminum parts are involved, anodizing helps reduce several common risks:

- Stronger corrosion resistance in moisture and salt exposure, helping surfaces stay stable in real road environments

- Better wear resistance during assembly and installation, reducing scratches that can become corrosion starting points

- A finish that is less likely to peel under vibration because the oxide layer is part of the metal, not a film on top

- More stable appearance and cleaner metal texture for long-term visual consistency

- More consistent assembly and mass-production outcomes, supporting lower after-sales risk for OEM/ODM and wholesale customers

7. Limitations to Keep in Mind

Anodizing is highly effective, but it is not universal. Common limitations include:

- Best suited to non-ferrous metals (such as aluminum, titanium, magnesium); steel is not treated the same way

- If the oxide layer is deeply breached, the underlying metal can become vulnerable in harsh conditions

- The surface can be harder but also more brittle than the base metal under severe impact

- Large or complex parts can increase process cost and control requirements

- Color and special-effect options can be more limited than painting or powder coating

8. Overall: Why CN360 Uses Anodizing for LED Headlight Bulbs & Small Automotive Bulbs Components

For LED headlight bulbs and small automotive bulbs, reliability is measured by stability over time—not just initial brightness. That is why CN360 uses anodizing on relevant aluminum components. By reinforcing the surface with an integrated oxide layer, anodizing supports durability and long-term consistency in harsh automotive conditions.

In practical terms, anodizing helps deliver better corrosion resistance in moisture, salt, and chemical exposure; better wear resistance during handling and installation; a finish that won’t peel easily under vibration; a more stable, premium-looking metal surface; and more consistent manufacturing outcomes for OEM/ODM and wholesale supply. The result is a product that stays cleaner, more stable, and less likely to trigger avoidable after-sales issues in the market.