Work lights rarely live an easy life. They sit low on bumpers, roof racks, forks, tractors, and heavy equipment—right where gravel impact, mud, salt spray, detergents, UV exposure, vibration, and thermal cycling all happen at once. In this environment, the LED and optics can be perfectly fine, yet the product still "fails early" in the customer’s eyes because the housing finish starts to chip, fade, creep-corroded edges appear, or the surface turns rough and tired.

That’s why many work-light housings—especially die-cast aluminum housings—are finished with powder coating rather than relying only on liquid paint.

What Powder Coating Actually Is

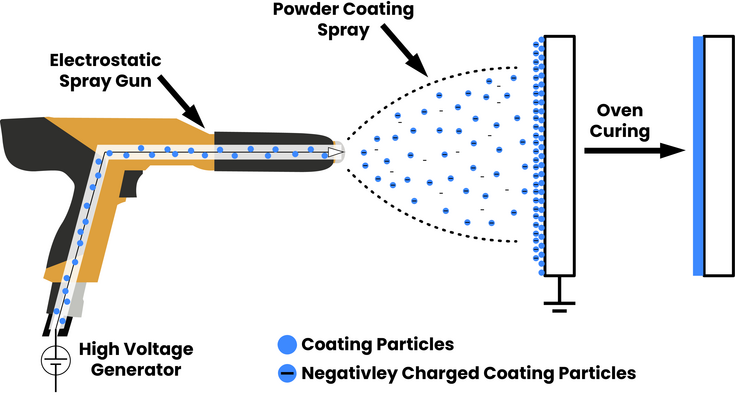

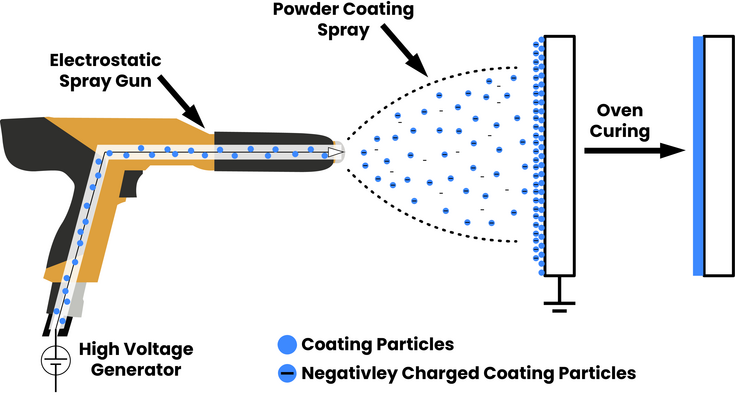

Powder coating is a dry finishing process where a powder (typically a blend of resin/binder, pigments, and additives) is electrostatically charged and sprayed onto a grounded part. The coated part then goes into an oven where the powder "melts, flows, and hardens" into a continuous protective film.

Unlike liquid paint, powder coating doesn't depend on solvent evaporation. It's fundamentally "powder → melt → cure into a solid film", which is one reason it's favored for durable industrial parts.

The Standard Process for Die-Cast Light Housings before powder

Most production lines can be described in three big tasks: pretreatment → application → curing. For die-cast LED/light housings, a very common shop-floor version looks like this:

-

Cleaning(often alkaline cleaning for aluminum die-cast parts)

-

Rinsing

-

Conversion/phosphating step (often listed as optional, but widely used to improve corrosion protection and adhesion)

-

Drying

-

Powder coating application

-

Curing (heat to liquefy/flow the powder, then solidify into the final film)

Why Powder Coating Fits Work Lights So Well

1) Durability that matches real outdoor abuse

Powder coating is widely chosen for a "resistant, high mechanical resistance" surface that can protect and decorate at the same time. For work lights, this translates into better resistance to the everyday little damage that adds up: stone chips, brush contact, tool bumps, and cleaning abrasion.

2) Corrosion protection is built into the system

Powder coating lines typically remove rust/oxides/grease and often create a "conversion layer" to improve corrosion protection and adhesion before coating. This matters because housing edges and corners are where corrosion often begins after chipping or thin coverage.

3) Cleaner compliance and less VOC burden

Powder coating is frequently highlighted as no-solvent finishing. In direct comparisons with painting for LED housings, one listed advantage is "powder recovery for reuse" and no VOC(Volatile Organic Compounds) generation (so no VOC destruction required).

4) One-coat capability and high material utilization

A common business reason powder coating is specified is that it can deliver strong results in one coat and achieve close to 100% material utilization. That helps when you’re trying to keep high-volume finishing stable and predictable without adding extra spray steps.

Limitations

1) Leveling can be less paint-smooth

Powder coating can have less leveling than paint (more orange peel). This is often a tradeoff: you choose durability and protection over a perfect automotive-clearcoat gloss.

2) Curing needs heat and energy

Powder coating requires oven curing. Curing is more energy intensive than paint drying because of higher temperature requirements. Temperature ranges vary by system: curing broadly at 110–250°C, depending on heating time and substrate thickness. For common thermoset powders, typical curing around 150–200°C for 10–20 minutes.

3) DFM realities: Faraday cage

The Faraday cage effect in electrostatic powder coating refers to what happens in deep recesses, narrow channels, or sharp inside corners: the electric field concentrates on the outer edges while the field inside the cavity becomes weak, so charged powder particles deposit on the outside and rim areas instead of being drawn into the recessed surfaces, leading to thin, uneven, or missed coverage in those hard-to-reach areas and potentially reducing corrosion protection.

If you’re selecting or sourcing work lights for real outdoor duty, focus on housings that use a controlled powder-coating process with proper pretreatment and DFM-friendly geometry. For more work-light housing and finishing insights, visit cn360led.com.