In automotive LED lighting, beam pattern and brightness get most of the attention—but long-term reliability often depends on something hidden inside: the LED board (PCB/base board). The board is not only an electrical platform. It also affects heat flow, vibration resistance, and service life. This guide explains the practical differences among aluminum MCPCB, copper MCPCB, FR-4, and FPC, and how to choose the right option for your application.

Why It's Called a "Base Board"

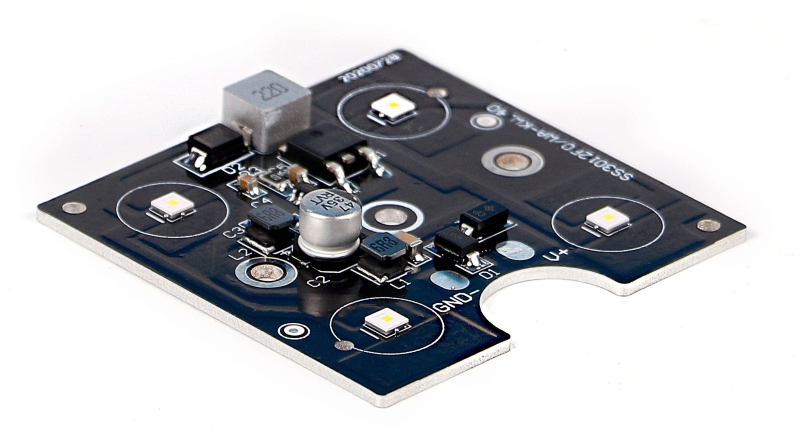

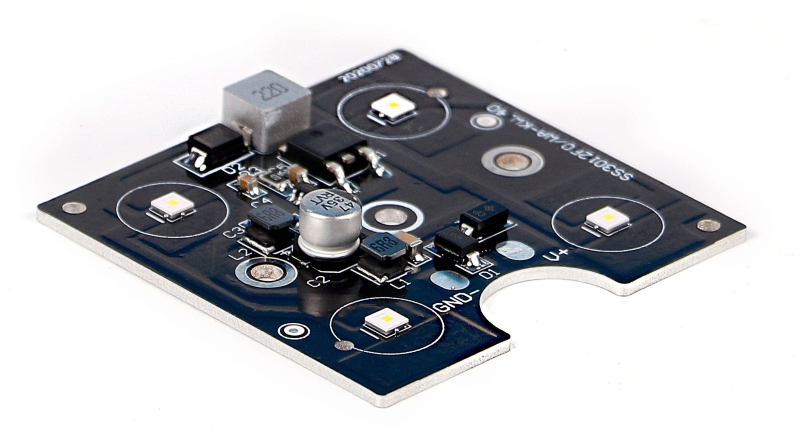

A typical LED board is built as a layered structure. The reason it's called a "base board" is that the circuit is formed on top of a base material that provides mechanical support (and sometimes a major thermal path). Most designs include:

-

Base material: aluminum, copper, FR-4, or a flexible substrate

-

Insulation (dielectric) layer: provides electrical isolation and (in metal boards) helps conduct heat

-

Copper foil layer: the conductive layer that becomes traces and pads

-

Etching process: removes unwanted copper to form the final circuit pattern

Understanding these layers helps explain why different board types behave differently in heat management and durability.

Aluminum MCPCB: The Mainstream, Cost-Effective Choice

Aluminum MCPCB is widely used in work lights, auxiliary lights, and many headlight LED modules because it balances cost and thermal performance well.

-

Strengths: strong value for money and mature manufacturing

-

Thermal benefit: better heat transfer than standard FR-4 for LED applications

-

Durability: good mechanical strength for vibration-heavy environments

Limitations: Thermal performance is generally weaker than copper MCPCB under the same structure. High-power, high-heat-density designs may need stronger overall thermal design (better TIM, housing heat path, and airflow management).

Best for: Most general automotive LED lighting where cost control and stable quality are required.

Copper MCPCB: Stronger Heat Dissipation With a Higher Price Tag

Copper MCPCB is chosen when thermal demands are extreme—high power, long runtime, limited space, or strict temperature control requirements.

Limitations: Significantly higher cost (often several times more than aluminum solutions) and requires tighter process control and careful design to justify the added cost.

Best for: High-performance products and applications where temperature margin is critical, such as our Product MT20:

MT20 features a high-power 20W LED chip paired with a customized glass lens, along with intelligent prevention of power loss for more stable output, and an IP67 waterproof rating for reliable performance in harsh conditions.

FR-4 (Fiberglass PCB): Great for Complex Circuits, Needs Thermal Help

FR-4 is the standard PCB material used across electronics. It's strong, affordable, and supports complex circuit layouts—often with double-sided or multi-layer designs.

-

Strengths: excellent for complex circuits and high component density

-

Design flexibility: easy to build with multiple layers and advanced routing

-

Supply stability: widely available and cost-effective

Limitations: FR-4 itself is not a strong heat conductor. For high-power LEDs, thermal performance must be reinforced with heavy copper planes, thermal vias, proper TIM selection, and external metal heat paths.

Best for: Driver/control boards and LED modules with complex electronics rather than extreme heat loads.

FPC (Flexible PCB): Ideal for Small Lamps and Tight or Curved Spaces

FPC is widely used in small automotive lamps because it can bend and fit into compact, curved, or irregular spaces.

-

Strengths: flexible, thin, and lightweight

-

Packaging advantage: enables easier routing and assembly in tight spaces

Limitations: Thermal and mechanical protection can be more limited than rigid boards. Reliability depends heavily on fixing method, bending radius control, and heat exposure management.

Best for: Small lamps such as position lights, interior lights, license plate lights, and other compact applications.

A Simple Decision Framework: 3 Questions to Choose the Right Board

-

How high is the heat density and runtime? High power + long runtime + limited space → consider copper MCPCB or a reinforced aluminum thermal design.

-

How complex is the circuit? More components and control functions → FR-4 (double-sided or multi-layer) is usually more practical.

-

Is space tight or curved? Curved housing or compact packaging → FPC is often the best fit.

Key Takeaway

The LED board is not just a circuit carrier—it is part of your thermal and reliability system. Aluminum MCPCB offers strong cost-performance for mainstream products. Copper MCPCB supports high-performance, heat-sensitive designs. FR-4 enables complex circuitry but needs thermal reinforcement for high-power LEDs. FPC excels in small, space-limited lamp designs. Choose based on heat density, circuit complexity, and packaging constraints—not only on brightness targets.To learn more about our automotive LED lighting solutions and OEM/ODM projects, visit cn360led.com.